Energy characterization hub

This technical hub is equipped with instruments to measure change of state temperatures, latent heat, mass heat capacity, Cp, Tg and the heat conductivity of the materials studied. It comprises:

- A DSC 8000, which functions according to the exclusive PerkinElmer power compensation principle. The measuring head is composed of two independent furnaces made of a platinum-iridium alloy, and each furnace is fitted with independent temperature sensors uniformly distributed over the base. The power supplied to each furnace is measured directly, which avoids having to convert differences in temperature into energy. In the DSC 8000, we have adapted the liquid nitrogen cooling system, CLN2, making it possible to work as from -180°C, and an autonomous system allowing analyses to be conducted as from -100°C. The temperature range is therefore -180°C to +750°C. The platinum furnaces are chemically inert and oxidation-resistant with a better thermal conductivity. They can be used for analyses under oxygen conditions at temperatures of more than 600°C without any risk of corrosion. The mass of the furnaces is much lower than that of conventional furnaces. The rate of heating and cooling is ultra-fast (0.01 to 750°C in a minute).

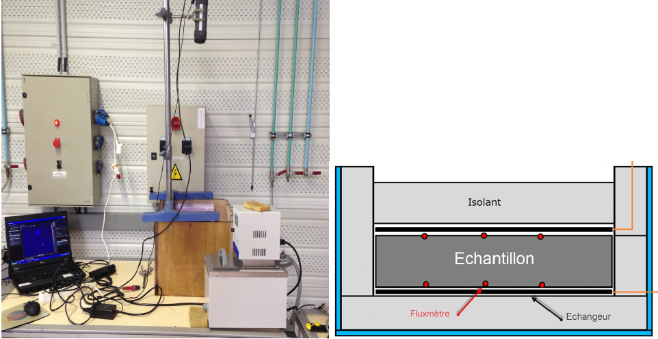

- A heat flux sensor of 10- to 20-mm thick. This consists of cooling tubes with an outer diameter of 6 mm and a sensitivity of the order of 100μV/(W/m2). The test bench has two water heat exchangers (each fitted with a heat flux sensor) and a thermostatic bath. The heat flux sensors are used to calculate the average temperature and the density of the flow crossing the material to be analyzed. Type T thermocouples give the temperature of the surface when it comes into contact with the material.

PERKIN-ELMER DSC 8000 for power compensation calorimetry

250x250 CAPTEC heat flux sensors reinforced with 0.3-mm copper plates