“Terre Crue” (rammed earth) project

Part of our research activities are focused on the construction of load-bearing masonry made of rammed earth.

We have recently developed a method for producing compressed earth blocks without using chemical binders such as cement or calcium hydroxide. This method involves applying a very high compaction pressure of up to 100 MPa and a bio-cementing process. When earth blocks are fabricated in this way, their rigidity and resistance are comparable to those of conventional masonry materials, and their hygrothermal properties are much better.

This research was financed by the European Commission, the Regional Council of Nouvelle Aquitaine, the Côte Basque-Adour conurbation and the Departmental council of the Pyrénées-Atlantiques.

Development of a manufacturing process

The objective is to develop a process for manufacturing compressed mud bricks with the lowest possible environmental impact.

The final products must have the regulatory characteristics required to be used in construction: the different properties are therefore assessed from the material scale to the wall scale and the product.

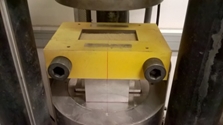

The manufacturing method developed is based on a hypercompaction process (up to 100 MPa). Specific moulds have been developed.

Mould for the manufacture of hypercompacted mud bricks.

Stabilization and durability

In order to limit the environmental impact of the products developed while improving the durability of compressed raw earth-based materials, alternative stabilization methods to hydraulic binders are tested: mechanical, chemical, thermal, waterproofing agents and biostabilization. In order to better characterize the effect of stabilization methods on properties, the link with the microstructure is established by measurements of mercury porosimetry, nitrogen adsorption and X-ray microtomography.

Various tests of water resistance of the materials are carried out: contact, absorption, suction, erosion,... The freeze-thaw resistance is also studied.

Measurement of the compressive strength of raw earth bricks.

Hygro-thermal exchanges and indoor comfort

The hygrothermal regulating capacity of stabilized raw earth-based materials is evaluated by hygroscopic exchange measurements on the material or product (MBV method), and at the wall scale by means of a double chamber regulated in temperature and humidity to simulate winter or summer conditions. Models of the contribution of raw earth to winter or summer comfort in buildings are then developed on the basis of its data.

The influence of the incorporation of vegetable fibres on hygro-thermal behaviour is currently being studied.

Another area of research studied is the contribution of raw earth to the retention of pollutants to improve indoor air quality and visual properties.

Development of eco-materials by recycling by-products

This research theme concerns the development and characterization of cementitious material formulations incorporating industrial by-products (insertion of steel mill slag as aggregates for heavy concrete, substitution of sand by oyster shells, use of recycled aggregates from the demolition of buildings, etc.).

The recovery of these by-products makes it possible to limit the environmental footprint of the concretes developed, particularly from the point of view of limiting the depletion of natural resources. An efficient approach is applied to ensure the durability of the cementitious materials developed. A technical and economic optimization of the concrete manufacturing steps is carried out, based on life cycle analyses.