Electrical FracturingIndustrial partner: ITHPP

Project name: supervising the PhD of Tony Imbert with the CIFRE (National research and technology association)

Subject: Contribution to the study of electric discharges in fluids and to the optimization of shock wave generation

Start date: January 15, 2019

End date: January 14, 2022

Industrial partner: ITHPP

Scientific managers: Thierry REESS

Permanent member of the SIAME involved: Antoine SILVESTRE de FERRON

Type of contract: cooperation agreement

Partners: Bucur NOVAC

Project description

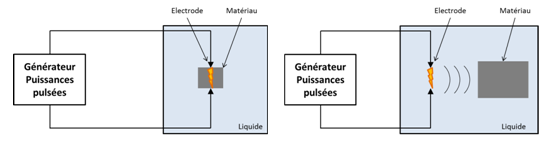

The company ITHPP located in Thégra, France and the SIAME laboratory are working in partnership on studies centered on Plasma Blasting Technology (PBT). This method consists in creating a shock wave by electrical breakdown. The shock wave is used to pulverize solid materials, either to separate the various components, or more simply to fracture them. Two principles can be applied:

- Delocalized, or indirect, in which the shock wave is transmitted to the material through a liquid medium.

- Localized, or direct, in which the discharge takes place directly within the material.

Principle of the localized and delocalized methods

This method has many applications (separation and crushing of waste, powdering of products, skinning of concrete, ceramic sintering, rock fracturing, electromagnetic shaping, etc.) but individual processes first need to be optimized.

his scientific project is a continuation of previous work on electrical fracturing and is nested within the PULPA Chair at Bucur NOVAC. The goal is to establish an experimental database to understand, predict and optimize rock crushing from electric arcs in a fluid. In particular, the influence of all the parameters related to the discharge circuit will be studied in order to master the phenomenology of the discharge, and consequently to perfectly control the pressure wave generated.

Of course, this project will inevitably go through a phase of significant improvement of the process: the objective being to obtain maximum damage for the lowest possible input of electrical energy.